IMPERIAL STANDARDS

Mechanical Tolerances

| Dimension | Steel thickness | Allowable tolerance – finished cores |

|---|---|---|

| A | All | ±1/32 when A £ 2 +1/16 – 1/32 when A > 2 £ 6 +1/8 – 1/16 when A > 6 £10 ±1/8 when A > 10 |

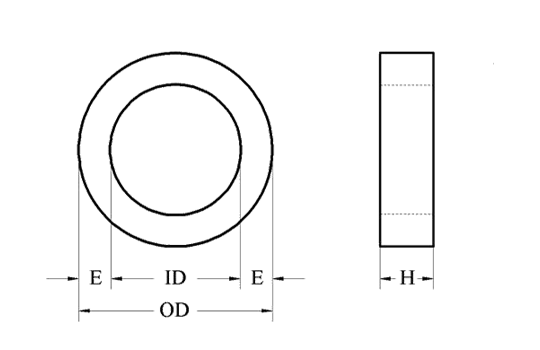

| E | All | ±1/64when E £1/4 +1/32 – 1/64,when E > 1/4 £1 ±1/32,when E > 1 £ 3 ±1/16,when E > 3 |

| F | 2 and 4 mil | +1/32 – 1/64 |

| 12 mil | ±1/32when F £ 6 +1/16 – 1/32,when F > 6 |

|

| D | All | +1/32 – 0 when E £ 3 +1/16 – 0 when E > 3 |

Electrical Guarantees

Guaranteed magnetic properties of annealed non-impregnated toroids are corresponded to standard limiting properties for a used grades of grain-oriented silicon steel.

Note:

Compatible only for toroids with inner diameter greater than 1-3/16” and strip width greater than 3/8”; for steel thickness 11-14 mil (inner diameter 3/8” and width 1/8”, for steel thickness 4mil).

In epoxy coated or impregnated toroids occur magnetic degradation due to mechanical stresses.

In these toroids the core losses are increasing approximately on 20-30% in comparison with raw material.

| Grade | Thickness, mil | Stacking factor | Maximumspecific core loss, W/lb | |||

|---|---|---|---|---|---|---|

| 60 Hz | 400 Hz | 2 kHz | ||||

| 15 kG | 17 kG | 15 kG | 0.5 kG | |||

| M6 | 14 | 0.96 | 0.66 | 0.94 | – | – |

| M5 | 12 | 0.95 | 0.58 | 0.83 | – | – |

| M4 | 11 | 0.95 | 0.53 | 0.76 | – | – |

| M0H (HiB) | 12 | 0.96 | – | 0.63 | – | – |

| M0H (HiB) | 9 | 0.94 | – | 0.60 | – | – |

| – | 4 | 0.92 | – | – | 6.8 | – |

| – | 2 | 0.89 | – | – | – | 8.6 * |

Note:

*- not guaranteed