IMPERIAL STANDARS

MECHANICAL TOLERANCES (CONFORMS TO EIA STANDARD RS-217):

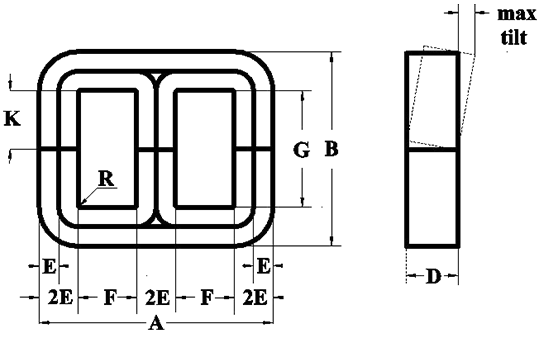

- A & B- Exterior dimensions. Held to maximum tolerance only to ensure overall enclosure fit.

- D & E- Dimensions held to + tolerance, to ensure magnetic qualities under all applications.

- F & G- Window dimensions. Held to a minimum tolerance, only to ensure coil fit.

- K & R- Reference dimensions only.

MEASURMENT:

- D- Dimension measured by caliper at any point on the either core half.

- E- Dimension measured at the butt joint.

- F & G- Dimensions measured at the shortest point, at least twice the radius R from the edge of the window.

| Dimension | Steel thickness | Allowable tolerances-finished cores |

|---|---|---|

| A | 4 mil | +3/32 max when A ≤ 5 +3/16 max when A > 5 ≤ 10 +5/16 max when A > 10 |

| 12 mil | +1/8 max when A ≤ 5 +1/4 max when A > 5 ≤ 10 +3/8 max when A > 10 |

|

| B | 4 mil | +3/32 max when B ≤ 5 +5/32 max when B > 5 ≤ 10 +1/4 max when B > 10 |

| 12 mil | +1/8 max when B ≤ 5 +3/16 max when B > 5 ≤ 10 +5/16 max when B > 10 |

|

| D | 4 and 12 mil | +1/32 – 0 when D <1 +3/64 – 0 when D >= 1 < 2 +1/16 – 0 when D >= 2 +5/32 – 0 when 2E > 2-1/2 |

| 2E | 4 and 12 mil | ±1/32 when 2E ≤ 1 +1/16 – 1/32 when 2E > 1 ≤ 2 ±1/16 when 2E > 2 |

| F | 4 and 12 mil | -1/64 min |

| G | 4 and 12 mil | -1/64 min |

| K | All | G/2 if G ≤ 5 G/3 to nearest 1/16 if G > 5 |

| R | All | 1/16 when F ≤ 2 & G ≤ 2 1/8 when F or G >2 and F&G ≤5 5/32 when F or G > 5 |

| Tilt | 4 and 12 mil | 1/32 max when B < 3-1/2 1/16 max when B >=3-1/2 |

Electrical Guarntees

| Quality grade | Steel thickness, mil | Test conditions Bm, kG,f, Hz | Specificcore losses,,W/lb | Specific apparent power of metal, VA/lb | VA ofgap per phase | |

|---|---|---|---|---|---|---|

| Standard | 12 | 15 | 60 | 1.1 | 1.75 | 5.0 x A |

| Standard | 4 | 15 | 400 | 12.0 | 13.1 | 29.9 x A |