METRIC STANDARS

Mechanical Tolerances

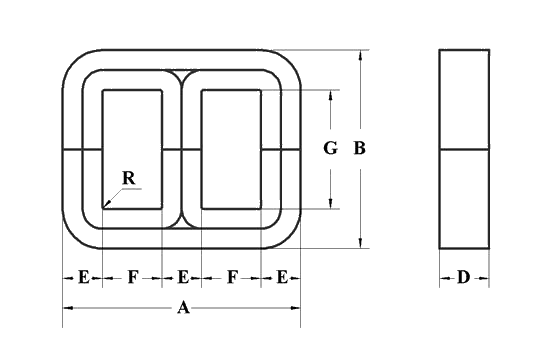

- A & B- Exterior dimensions. Held to a minimum tolerance, only to ensure overall enclosure fit.

- D & E- Dimension held to + tolerance to insure magnetic qualities under all applications.

- F & G- Window dimensions. Held to a minimum tolerance, only to ensure coil fit.

MEASURMENT:

- D- Dimension measured by caliper at any point on either core half.

- E- Dimension measured at the butt joint.

- F & G- Dimension measured at the shortest point, at least twice the radius R from the edge of the window.

| Quality grade |

Quality code |

Thickness, mm |

Test conditions,(3) |

Guaranteed values for bonded, cut or uncut cores |

|||

|---|---|---|---|---|---|---|---|

| Bm, T | f, Hz | W/kg (4) | VARm/kg (1) | VARg/kg (2) | |||

| Standard | ELA | 0.30 | 1.7 | 50 | 2.4 | 9.90 | 27xAc minWt. min(a=0.075mm) |

| Standard | ELH | 0.10 | 1.5 | 400 | 26.4 | 28.60 | 111xAc minWt. min(a=0.05mm) |

- VARm/kg – specific reactive power of metal.

- VARg/kg – specific reactive power of air-gap, a = air-gap length

- Test conditions based upon mono-phase excitation of center leg.

- Values are 20% higher than for C-core because of third harmonic flux.